Basic HTML Version

SompioMining

29

VTT has a multidisciplinary offe-

ring covering the whole life cycle

of the mine

(Figure 1).

Our target

is to develop technologies that uti-

lize nature’s resources in environ-

mentally, socially and economically

sustainable way. The main focuses

are on sustainable utilization of raw

materials and tailings, and under-

standing of the fate of wastes and

waters generated by mining opera-

tions. Mine waste management and

utilization as products, stability of

solid waste in mine sites, and ge-

nerally finding economically sustai-

nable processes for low grade ores

are studied at VTT.

Many on-going projects at VTT

belong into the TEKES Green Mi-

ning program and are carried out to-

gether with GTK (Geological Survey

of Finland) and industrial partners.

One example of hydrometallurgical

process development work is the

improved recovery of rare earth me-

tals from different sources, which

are studied in REPRO (Assessment

of rare earth metal recovery pro-

cess) project. The unique properties

of rare-earth elements (REE) make

them essential to emerging techno-

logies in environmental, energy effi-

ciency and health solutions. Future

concerns regarding security of REE

supply in Europe and other count-

ries result from China’s near mo-

nopoly of production until the year

2010.

The use of both primary and se-

condary sources and wastes as raw

material resources are looked at to

improve REE supplies. The recove-

ry of rare earth metals from waste

materials is currently challenging,

and new economically and environ-

mentally sound technologies are

necessary. VTT is active in EU advi-

sory group ERECON (European Rare

Earth Competence Network) as well

as in EUs raw materials and re-

cycling groups in European Innova-

tion Platform and KIC Raw Matters

with other Finnish partners.

Another example dealing with

topical mine water management

is PUMI project (Purification and

monitoring concept for mining wa-

ter treatment based on new water

technologies). In this work new

technologies, such as forward os-

mosis, are applied to process and

waste waters from the mine sites.

Advanced knowledge of existing and

developing water treatment techno-

logies in addition to the knowledge

of different hydrometallurgical unit

processes in the mines are combin-

ed for the purification concept. Fit

for purpose water concept means

that the quality of water is matched

to the requirements for the end use.

The requirements of process water

are highly dependent on specific in-

dustry applications. Every mine site

is specific in terms of ore type, gan-

gue material, plant situation, water

quality etc. Water quality may have

significant impact on the performan-

ce of separate unit processes and

the whole process chain even up to

the form of solid waste that is ge-

nerated. Therefore, water recycling

and reuse needs to be assessed in-

dividually case-by-case in a holistic

way. Environmentally beneficial wa-

ter recycling and reuse projects can

also return a significant economic

benefit. Technologies that are able

to generate sufficient quality water

at a reasonable cost are required.

Closedure project looks how

the mine is safely closed after its

lifetime, including the necessary

integration of mine closure process

to the mine lifecycle. The goal is

to give guidance on selecting right

technologies and approaches that

are crucial for a successful mine

closure. Also this work is useful for

the authorities to support smooth

permitting. Within this work, in col-

laboration with GTK, a wiki-based,

modular, and updatable web

resource is created. The goal is to

improve mine closure and reduce

adverse environmental impacts,

improve the public knowledge and

societal impacts.

The mine waste and waste faci-

lities are the most prominent sour-

ces of pollution after mine closure.

In order to minimise the environ-

mental impacts, it is important to

predict the long-term behaviour of

waste using proper characterisati-

on methods, and to select suitab-

le solutions for closure of waste

areas. Another important aspect is

the post-closure water treatment,

where reliable but at the same time

cost-effective methods with low

maintenance requirements would

be needed. In the Closedure project

both active and passive water tre-

atment solutions are evaluated for

their suitability, and selected passi-

ve methods will be studied in order

to produce more information about

their long-time performance.

To predict the long term beha-

viour of disposed material and to

minimize the amount of waste itself

through efficient utilization, a pro-

per characterization of the waste

material is crucial. Also the met-

hods available to successfully close

a waste facility and to remediate

the impacted areas are dependent

on the geochemical processes deri-

ved from the properties of disposed

material.

These few examples show VTT’s

commitment to create sustainable

technologies for mining industry.

teknologioita, joiden avulla luonnonvaroja voidaan hyödyntää ympäristövastuu, yhteiskuntavastuu sekä

taloudellinen vastuu huomioiden. Tutkimusalueitamme ovat muun muassa uusien prosessien kehittäminen

köyhille malmeille ja jätemateriaaleille, kaivosten jätteiden ja vesien hallinta, jätteiden hyötykäyttö sekä

niiden stabiilisuus ja sijoitus- tai hyödyntämiskelpoisuus.

Useat VTT:llä käynnissä olevat tutkimushankkeet kuuluvat TEKES:n Green Mining –ohjelmaan. Hankkeita

toteutetaan yhteistyössä teollisuuden sekä muiden tutkimuslaitosten kuten GTK:n kanssa. Yksi esimerkki

hydrometallurgisten prosessien kehittämistyöstä on Repro-projekti, jossa tutkitaan harvinaisten

maametallien tehokkaampaa talteenottoa eri lähteistä. Harvinaisilla maametalleilla on erityisiä

ominaisuuksia, joita tarvitaan uusissa ympäristö-, energia- ja terveydenhoitoalan teknologisissa

ratkaisuissa. Harvinaisia maametalleja voidaan ottaa talteen primääristen raaka-aineiden lisäksi

jätemateriaaleista, mikä vaatii uusien teknologioiden kehittämistä. VTT on aktiivisesti mukana EU:n ERECON

(European Rare Earth Competence Network) –työryhmässä sekä muissa raaka-aineita käsittelevissä EU-

tason työryhmissä.

Esimerkkinä kaivosten vesien hallinnasta on Pumi-projekti, jossa kehitetään kokonaiskonseptia kaivosten

jäte- ja prosessivesille. Projektissa yhdist tään tietoa erillisten kaivosteollisuude yksikköoperaatioiden

vedenlaatutarpeista sekä nykyisillä ja uusilla vedenkäsittelyteknologioilla saavutettavasta veden laadusta.

Tavoittee a on kierrättää mahdollisimman paljon vettä kaivosteollisuuden prosesseissa. Veden laatu

vaikuttaa merkittävästi niin yksittäisten prosessien kuin koko prosessiketjun toimintaan sekä muodostuvan

jätteen koo tu ukse n. Jokainen kaiv s on malmin, harmemineraalien, prosessoinnin, veden laadun jn .

suhteen erilainen ja siten veden kierrätyksen mahdollisuuksia pitää tarkastella tapauskohtaisesti.

Positiivisten ympäristövaikutusten lisäksi veden kierrättäminen prosesseissa on usein myös taloudellista.

Kuva 1.

Sustainable mining

research at VTT

Päivi Kinnunen (Senior scientist), Justin Salminen (Senior scientist), Ulla-Maija Mroueh (Principal scientist)

Sustainable mining research at VTT

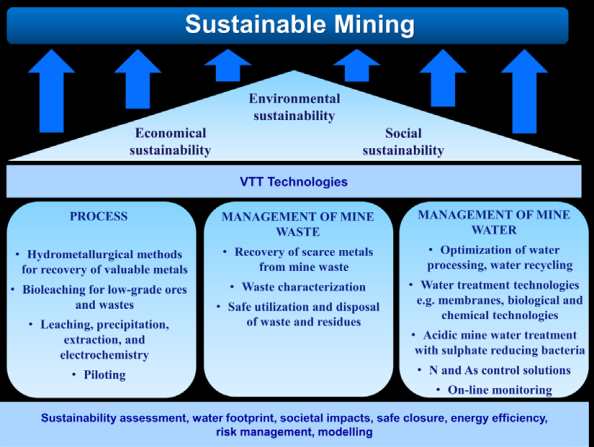

VTT has a multidisciplinary offering covering the whole life cycle of the mine (Figure 1). Our target is to

develop technologies that utilize nature’s resources in environmentally, socially and economically

sustainable way. The main focuses are on sustainable utilization of raw materials and tailings, and

understanding of the fate of wastes and waters generated by mining operations. Mine waste management

and utilization as products, stability of solid waste in mine sites, and generally finding economically

sustainable processes for low grade ores are studied at VTT.

Figure 1. VTT offering for sustainable mining.

Many on-going projects at VTT belong into the TEKES Green Mining program and are carried out together

with GTK (Geological Survey of Finland) and industrial partners. One example of hydrometallurgical process

development work is the improved recovery of rare earth metals from different sources, which are studied

in REPRO (Assessment of rare earth metal recovery process) project. The unique properties of rare-earth

elements (REE) make them essential to emerging technologies in environmental, energy efficiency and

health solutions. Future concerns regarding security of REE supply in Europe and other countries result

from China’s near monopoly of production until the year 2010.

Labtium Oy on ainoa laboratorio Pohjois-

maissa, joka pystyy tarjoamaan kattavasti

lähes kaikki geologisen tutkimuksen, mal-

minetsinnän ja kaivostoiminnan tarvitse-

mat kemialliset analyysipalvelut.

Labtiumilla on vahva kokemus geoke-

mialliseen ja ympäristögeokemialliseen

kartoitukseen ja tutkimukseen tarvittavis-

ta näyte-esikäsittely- ja analyysipalveluista.

Ennen yhtiöittämistä osana Geologian tut-

kimuskeskuksen tutkimusorganisaatiota

laboratorio on analysoinut laajasti 1970-lu-

vulta lähtien kaikki GTK:n kartoitus- ja tut-

kimushankkeisiin liittyvät näytteet.

Malminetsintään ja mineraalivarojen

arviointiin Labtium tarjoaa menetelmä-

valikoiman, joka vastaa kansainvälisesti

hyväksyttyjä best practice- menetelmiä.

Menetelmin suorituskykyä arvioidaan jat-

kuvasti osallistumalla useisiin kansainvä-

lisiin laboratorioiden välisiin vertailukokei-

siin sekä geologisten vertailumateriaalien

sertifiointiohjelmiin.

”Olemme aktiivisesti olleet myös raken-

tamassa uusien kaivosten laboratoriopal-

veluja. Voimme tarjota laboratoriopalvelut

täysin ulkoistettuna palveluna joko kiintei-

den toimipisteidemme kautta tai tarvitta-

essa asiakkaan omissa tiloissa kaivoksen

läheisyydessä”,

Heikki Niskavaara

Labti-

um Oy liiketoimintajohtaja kertoo.

Labtiumin tarjoamat malminetsinnän

laboratoriopalvelut sijaitsevat siellä mihin

etsintä – ja kaivostoiminta Suomessa on

keskittynyt.

Kaivosten toimintaa tukevista palveluis-

ta esimerkkinä on Labtiumin Sodankylän

laboratorio, joka tuottaa monipuolisia pal-

veluja pääsääntöisesti lähellä sijaiseville

Lappland Goldminers’n Pahtavaaran ja

FQM Kevitsan kaivoksille. Sodankylässä

tarjoamme asiakkaillemme analyysipal-

veluja kaivosten louhinnanohjaukseen,

rikastamojen prosessinohjaukseen ja ym-

päristön seurantaan mm. nopeita vesiana-

lyysejä.

Maailman pohjoisimmat geoanalyyttiset laboratoriot

Arctic Assays

Labtium is the only labora-

tory in the Nordic Countries

providing locally comprehen-

sive sample preparation and

analytical services for explo-

ration and mining.

Labtium can provide a

wide range of analytical and

expert services to support

the mining and mineral exp-

loration companies from ex-

ploration and development

stage to mine production

and environmental monito-

ring.

Labtium Oy is a fully inde-

pendent and impartial labo-

ratory company established

in 2007 after long history

of being part of the Geolo-

gical Survey of Finland and

tracking back to the 1940’s.

As we are working close

to our clients we can toget-

her tailor the whole testing

plan to fulfil as well as pos-

sible the particular require-

ments of specified minerali-

zation type.

Labtium can also provi-

de full range of services for

mining. In addition to the

preparation and analyses of

exploration and grade cont-

rol samples, we analyse pro-

cess samples from different

stages of the ore processing

starting from feeds to tails

including independent com-

mercial and umpire analysis

of the final products.

Labtium has focused its

services for exploration and

mining to regions in Fin-

land where the main activi-

ties are – namely Eastern

– and Northern Finland. As

an example of our services

to mining is the laboratory

in Sodankylä which provi-

des services e.g. for nearby

Lappland Goldminer’ Pah-

tavaara and FQM Kevitsa

mines. The service portfolio

covers grade control, various

types of mineral processing

samples as well as environ-

mental samples e.g. fast wa-

ter sample analyses.